Discover posts

Want your content to appear in Google AI Overviews in 2026? 🤖📄

This guide breaks down practical optimization strategies—from semantic context and structured headings to entity signals, clear intent, and content relevance—so your pages have a better chance of being featured in AI-driven summaries.

👉 https://gearupcode.com/optimiz....e-content-for-google

#aiseo #googleai #contentoptimization #searchengineoptimization #digitalmarketing #serp #aidrivensearch #gearupcode

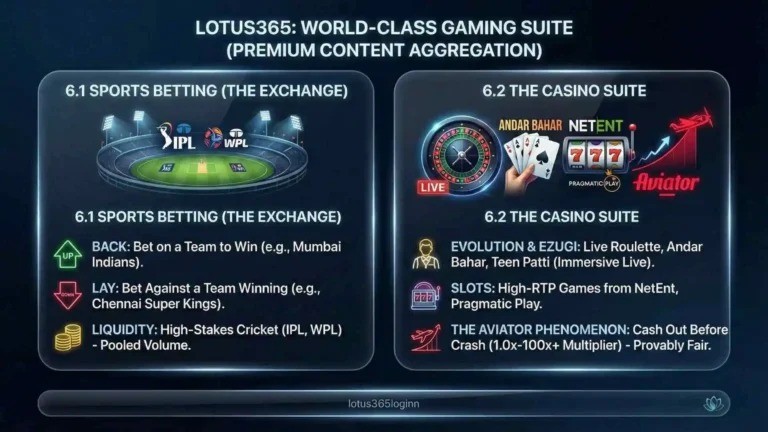

Lotus365 App – Secure Login, Features & Benefits | Lotus365Login

Explore the Lotus365 app with Lotus365Login for fast, secure access and a smooth user experience. Learn about key features, easy login steps, and why the Lotus365 app is trusted by users for reliable performance and convenience across devices.

http://lotus365loginn.com/

Lotus365 Login – Secure & Fast Access | Lotus365Login Official Platform

Lotus365 login gives users secure and instant access to the Lotus365Login platform. Enjoy smooth navigation, quick account access, and reliable services with a trusted and user-friendly login experience designed for convenience and safety.

http://lotus365loginn.com/

Upgrade your phone? Sell your mobile phone in Dubai and get top market value without delays. Enjoy smooth service and quick payment.

Visit us: https://gadzy.ae/sell/phone

#dubaimobilemarket #selloldmobile #phoneresaledubai #cashforphonedubai #techdubai #sellmyphone #onlinesellinguae #quickmoney #mobiletrade #easycash

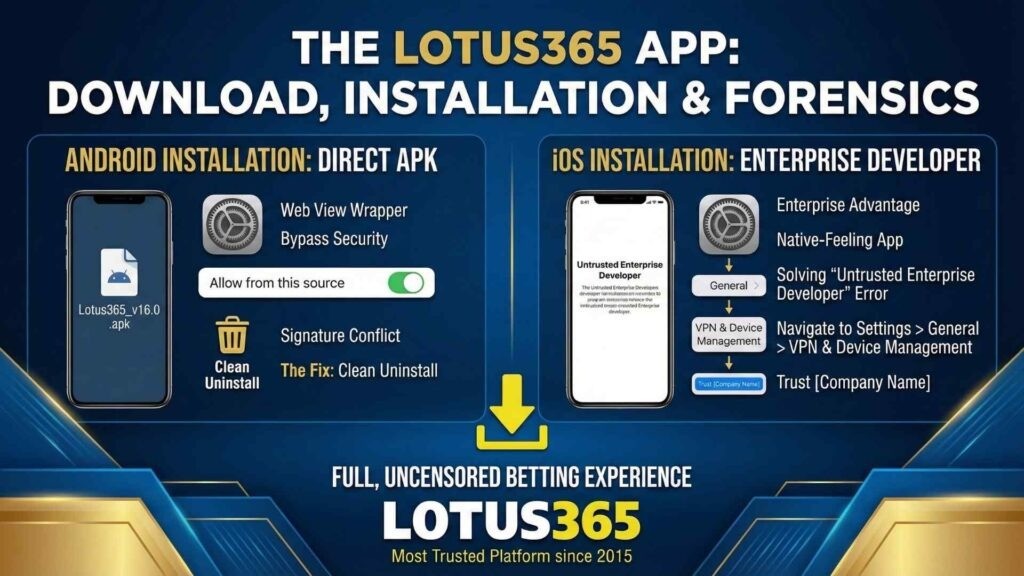

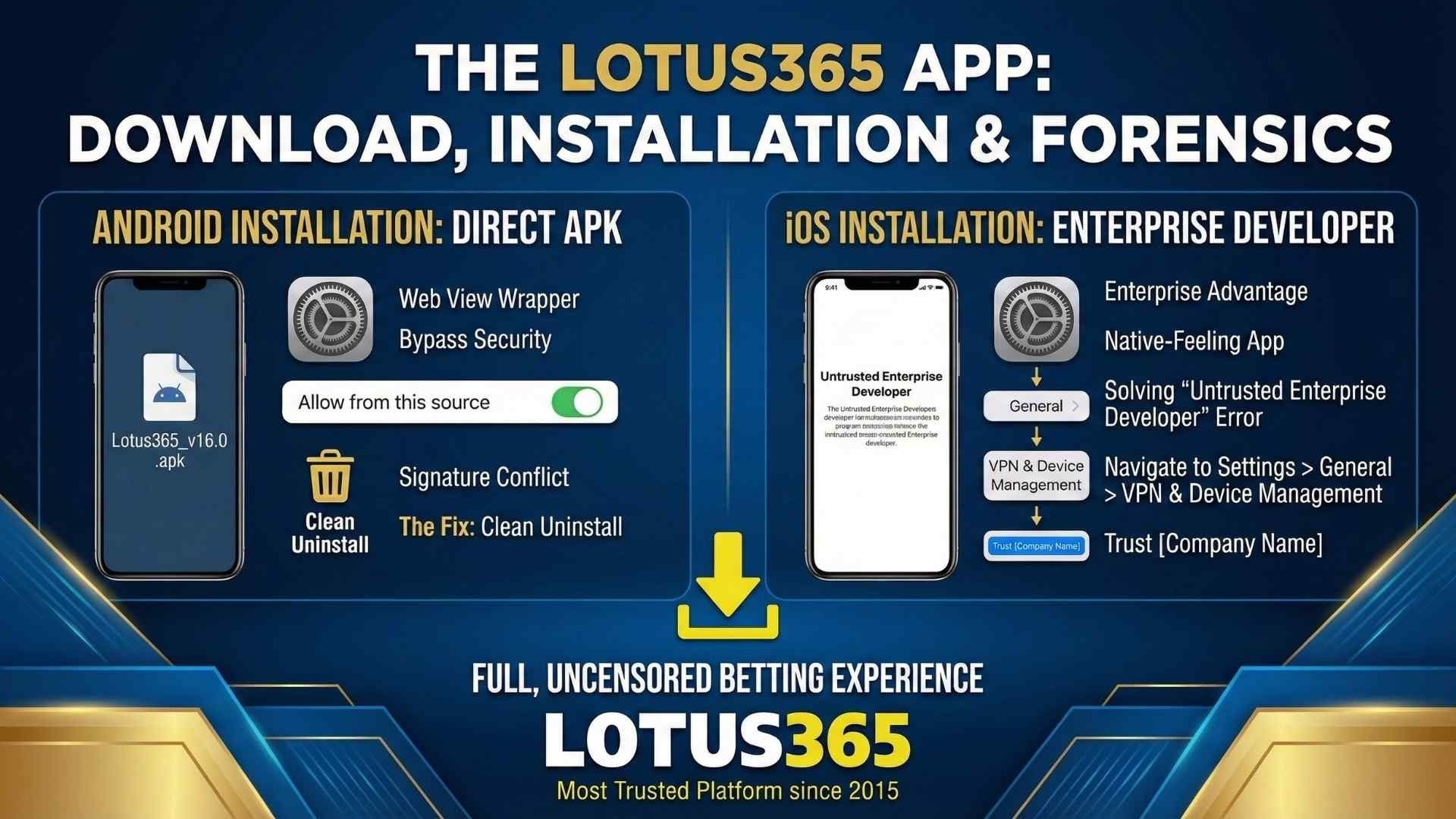

Lotus365 App Download – Secure & Fast Betting Experience | Lotus365loginn

Looking for a smooth lotus365 app download? Lotus365loginn offers a secure, fast, and user-friendly mobile app for sports **** and online gaming. Enjoy quick installation, easy navigation, safe transactions, and uninterrupted gameplay anytime, anywhere with the trusted Lotus365 platform.

http://lotus365loginn.com/

ORDER NOW: https://healthyifyshop.com/OrderMatsatoKnife

Matsato Knives are premium kitchen knives known for their meticulous design, high-grade materials, and sharp performance. Drawing inspiration from Japanese blade-making traditions, these knives blend ancient craftsmanship with contemporary innovation.

For More Information:

https://www.facebook.com/MatsatoKnifeOfficial/

https://www.facebook.com/MatsatoKnifePage/

Lotus365 App – Secure Login, Features & Benefits | Lotus365Login

Explore the Lotus365 app with Lotus365Login for fast, secure access and a smooth user experience. Learn about key features, easy login steps, and why the Lotus365 app is trusted by users for reliable performance and convenience across devices.

http://lotus365loginn.com/

Booking a premium airport transfer with NJ Limo ensures your journey to or from the airport is smooth, comfortable, and stress-free. The guide explains how choosing professional private car services gives you reliable timing, luxurious vehicles, and experienced chauffeurs who handle luggage and navigation for you.

For Full Details, Visit : https://www.njlimo.co/smart-tr....avelers-guide-to-boo